Model: CPO

Power Supply: 220V 1Ph

Application: Paint Stripping

Workong Temperature: 420℃

Cycle Time: About 2 to 4 hours

Fuel: Natural gas

Control: PLC control system

Color: Customizable

Burn Off Oven

Product Description

Burn Off Ovens are used frequently in the coatings, fibers, electric motors and plastics industry. Burn off ovens are designed for removing paint, powder coating, epoxies, lacquers, urethanes and other organic or inorganic compounds from a variety of parts, such as: racks, hooks, jigs, fixture. And also for cleaning polymers from a variety of metal parts, such as: moulds, extrusion dies, screws, nozzles, extruders, hot runners, breaker plates.

► Cleaning Process

First, the Primary Burner heats the pyrolysis chamber to 420°C, thermally decomposes the organic materials or polymers in a low oxygen atmosphere, the organic materials or polymers are removed as off-gas, and are driven through the afterburner that burns in a direct-flame, leaving only harmless H20 (Vapor) and C02 to exit the exhaust stack. During the process, a temperature sensor in the chamber monitors the rate of off-gas from the parts by measuring the stack temperature. When the stack temperature reaches a preset point, the control system turns on a water spray mist to cool the parts, lowering the off-gasg rate before it reaches an ignition state. The water spray also activates if the oven temperature exceeds its set-point temperature by 30°C.

► Applications

- Paint & Powder Coating stripping (Racks, Jigs, Fixtures, Paint hooks and hangers)

- Plastics stripping (Moulds, extrusion dies, screws, nozzles, extruders, hot runners, breaker plates)

- Auto-Parts and Engine Rebuilding

- Fiber & Chemicals

► Advantages

- Low labor cost and simple operation

- Siemens Touch-Screen PLC control system

- Cleaning is fully automatic

- Short cycle time (about 2 to 4 hours)

- Optional fuel (Natural gas/Propane gas (LPG)/Diesel) for burners

- Safety and no pollution

► Features

- Primary Burner – The Primary Burner heats the pyrolysis chamber to 420°C, organic materials become the off-gas. The burner flame is confined to the combustion chamber never touching the parts.

- Water Spray System – The water Spray System controls the rate of off-gas preventing damage due to ignition or over-heating in the chamber.

- Afterburner – The afterburner burn the off-gas at temperatures ranging from 650°C to 900°C, leaving only harmless water vapor and carbon dioxide to exit the exhaust stack.

- Explosion Relief Door – The explosion relief door in the roof of the oven allow excess pressure relief by automatically open and then closing immediately by gravity.

- Built-In Cart – A heavy-duty structural steel cart is included with the oven. The cart rolls outside the furnace on removable tracks, for ease of loading and unloading.

- Safety & Controls – Burn Off Ovens include controls the rate of off-gas preventing damage due to ignition or over-heated in the chamber. and a dual-element temperature sensor, water pressure safety interlock switch, Y-strainer, automatic solenoid valve, high/low gas pressure switch.

- Control Panel – Burn Off Ovens come standard with a control panel with PLC, HMI, circuit breaker, control relays, interlocks, and terminal strips.

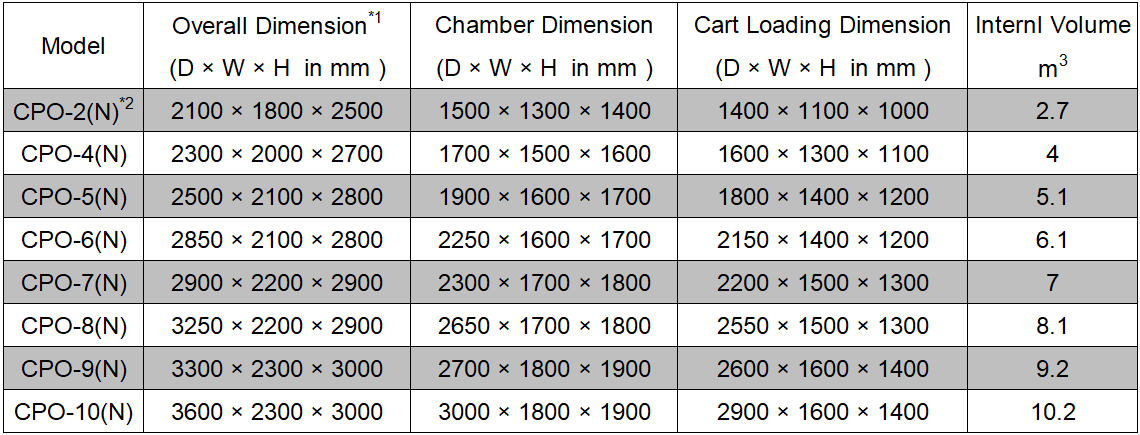

► Specifications

- Notes: Custom sizes are available per request.

- *1- Overall Dimension do not contain the height of the chimney.

- *2- Model:CPO-2(N), (N) stands for Natural gas, (P) stands for Propane gas (LPG), (D) stands for Diesel.

► Comparison

► Photo Of The Scene