Model: FCV

Power Supply: 380V 3Ph 50Hz (Customizable)

Application: Removal of Polymers from metal parts

Working Temperature: 450°C to 540°C

Heating: Electric heating

Temperature Control: PID Meter or PLC control

Control Accuracy: ±1°C

Color: Customizable

Fluidized Bed Cleaning Equipment

Product Description

Fluidized bed cleaning quipment is designed specially for cleaning polymers and organic contaminants from a variety of metal components. It’s a fast, cost-saving method. Parts immersed into the bath are cleaned by the high temperature environment within a bath media of fluidized aluminum oxide. Baskets are available for cleaning of small parts.

Fluidized bed cleaning method utilize heat exchange principle, when the compressed air blow in through the even air cap on it’s bottom, the aluminium oxide sand upward lightly boiling after electric heated, formed a very even temperature bath bed. Thermally decomposes the organic contaminants or polymers under a certain temperature and time, the organic contaminants or polymers are removed as off-gas and exit.

► APPLICATIONS

| The Parts To Be Cleaned | Industry |

|---|---|

| Spinnerets, Spinpacks, Filter Candles, Melt Pumps, Melt Pipes, etc. | Fiber (Chmeical fiber, Non-woven) |

| Extruder Screws, Film Blowing Dies, Breaker Plates, etc. | Extrusion |

| Hotrunner, Nozzles, Screws. etc. | Injection Molding |

| Filters, etc. | Film |

| Hooks, Jigs, Gratings, Hangers, Booth Grids, Reject Parts | Paint & Coating |

► ADVANTAGES

- The parts can be cleaned without thermal damage

- Precise temperature control.

- Suitable for different thermoplastic polymers, e.g. PET, PA, PP, TPE, PB, PBT, PC, PMMA, ABS, PVC, PTFE and PEEK, etc.

- Short cleaning cycles and low energy consumption.

- Simple operation.

- Fast cleaning minimizes production equipment down-time

► FEATURES

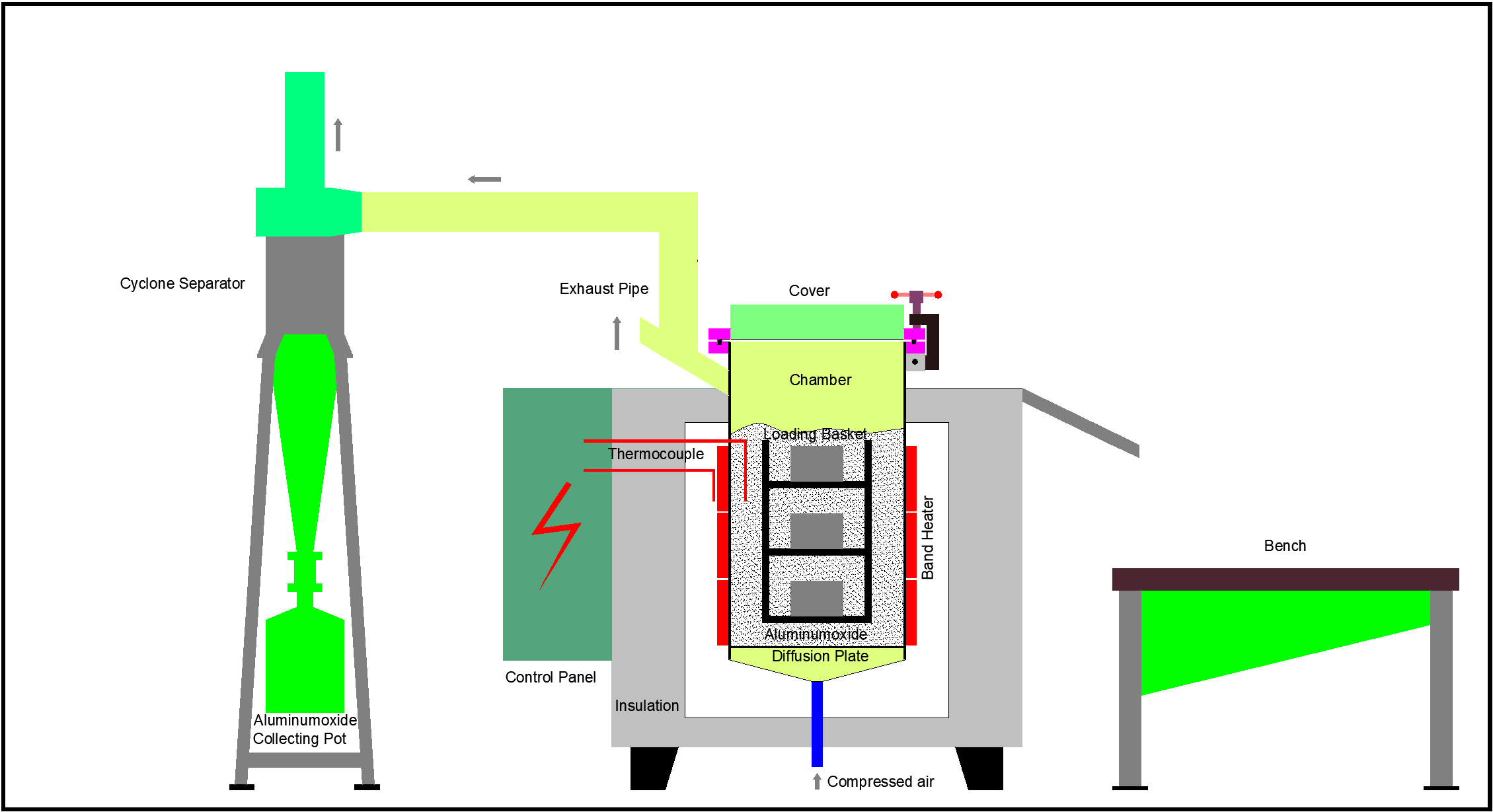

- Band heaters– The band heaters heats the chamber to 450°C – 540°C. Electrical band heaters transfer the heat to aluminum oxide particle

- Air cap– The compressed air blow in through the even “Air cap” on it’s bottom diffusion plate, the aluminium oxide sand pellets upward lightly boiling like air fluid after electric heated, formed a very even temperature bath bed.

- Cyclone Separator– The waste gas exhausted enter into cyclone separator through T-shape adapting pipe and S-type adapting pipe, make the sand pellets mixed in the air flow separated and fall into the down sand collecting pot, the waste air will be drawn out by fan.

- Bench– After the cleaning, the basket will be hung into the bench for cooling.

- Control Panel– Fluidized bed cleaning system come standard with a control panel, circuit breaker, control relays, interlocks, and terminal strips. The control panel is factory pre-wired prior to shipment.

- Air Flowmeter – Each unit comes with a front panel flowmeter to adjust airflow with settings for optimal flow per temperature.

- Off-gas treatment unit – The generated off-gas out of the system are pumped into the water scrubber where condensates are collected and rush out with water. (Optional)

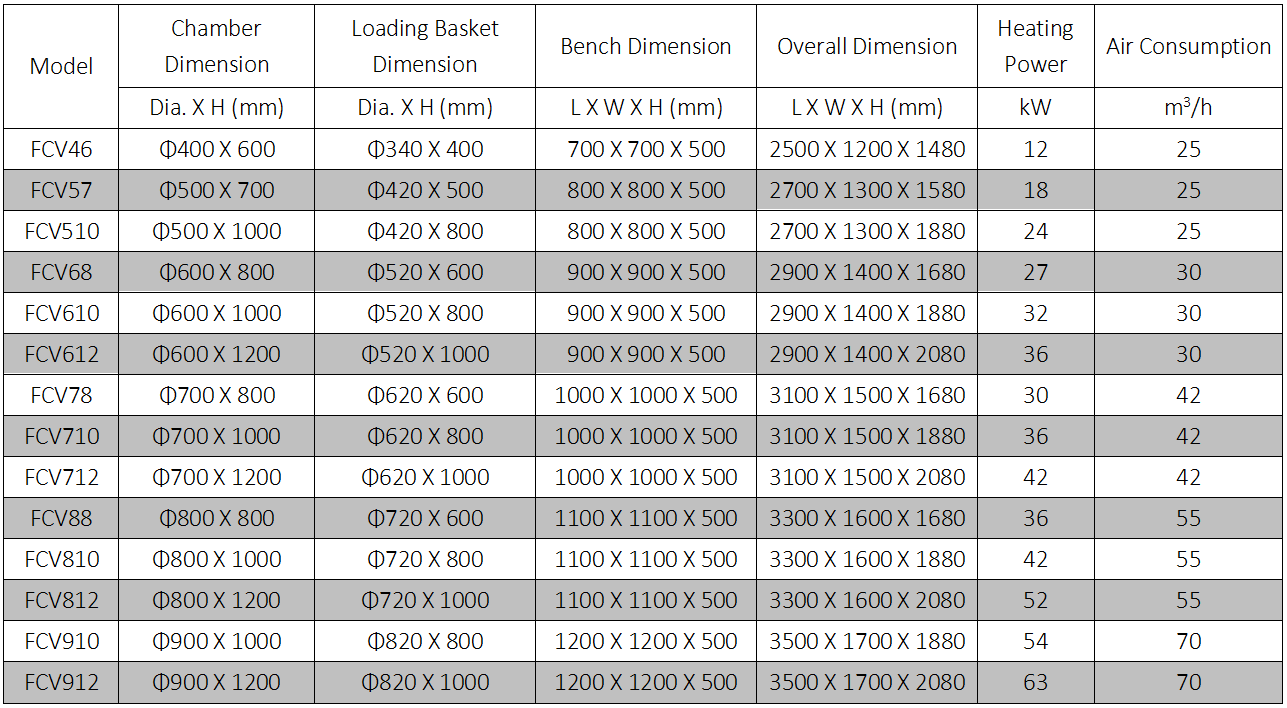

► SPECIFICATIONS

Note: Custom sizes are available per request.

Note: Custom sizes are available per request.

► CLEANING PROCESS

The cleaning temperature of chamber inside is depended on the kinds of polymers and typical cleaning temperature is 450°C – 540°C. After the temperature of chamber inside reaches to the setting temperature, the parts to be cleaned are put on the basket specially designed and the basket is immersed into the hot fluidized bed . Now the thermal cleaning process is started.

The parts to be cleaned are totally immersed in the aluminum oxide fluidized by compressed air blown in through the even air cap on it’s bottom, the aluminium oxide sand upward lightly boiling. Electrical band heaters transfer the heat to aluminum oxide particles which are the heat transfer medium and these particles are moved by compressed air and at the same time, particles also heat its surrounding air. The hot air heated in this way burns the polymers and organic contaminants on the parts to be cleaned. Here, the function of aluminum oxide particles is only for heat transfer and its low velocity is only 600 – 800 mm/min. Therefore, no damage even to the parts.

During the cleaning process, all organic residues such as polymer removed by thermal oxidation and become the off-gas without melt and the off-gas come out. Very few of aluminum oxide particles may come out with off-gas, and the particles are collected by a cyclone separator and are reused again.

► CLEANING CASE