Model: BCT

Power Supply: 380V 3Ph 50Hz (Customizable)

Application: Spinning packs

Solution: TEG (Tri Ethylene Glycol)

Working Temperature: 275°C

Heating: Electric heating

Temperature Control: Meter or PLC control

Control Accuracy: ±1°C

Color: Customizable

TEG Bath Cleaner

Product Description

TEG Bath Cleaning System is mainly used in the chemical fiber industry. It is designed for cleaning spinnerets, spinpacks and filters of PET.

► ADVANTAGES

- Single/Double/Triple pot configuration

- The cleaning is fully automatic

- Water cooling system

- Cleaning cycle is adjustable as per requirement

- Low power consumption

- All Stainless Steel structure

► CLEANING PRINCIPLE

Tri Ethylene Glycol (TEG) is a colorless, transparent, neutral oil liquid. When being heated to the boiling temperature, there will be a effect of melting and alcoholysis to the polymers. As of this characteristic, put the parts to be cleaned into the TEG solution, heat the TEG solution to 275 °C (limit boiling point of 286 °C ), the polymers attached to the parts will be melted.

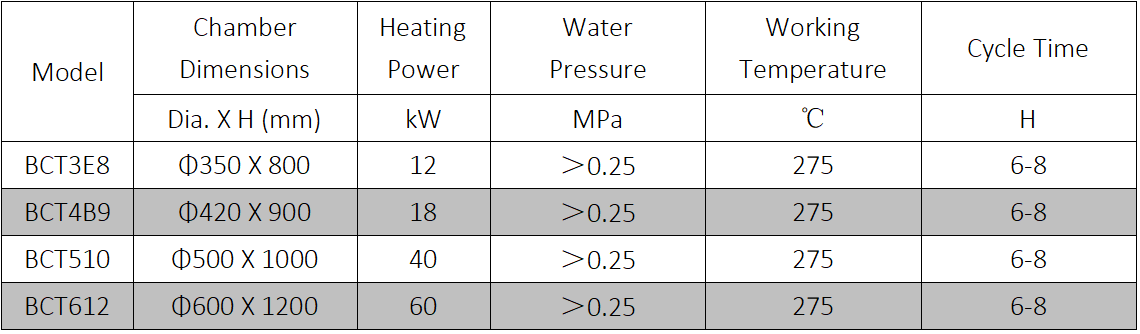

► TECHNICAL SPECIFICATION

Note: Custom sizes are available per request.

Note: Custom sizes are available per request.

► FEATURES

- Cleaning Pot – made of stainless steel, with a cooling jacket wrapping the barrel for cooling the temperature of TEG solution after the claening by putting in the cooling water to the jacket and drain out in the other side.

- Cover – elliptic, for gathering the vapor of TEG, intergrated with a condenser which actually is a tube type heat exchanger. The cooling water flow through the shell side and the vapour of TEG go through the tube side, after the cooling, changed into the TEG solution again, and then back to the cleaning pot from the upper flexible metal tubing.

- Electric Heater– flanged type, installed at the bottom of the cleaning pot, directly contact with the TEG solution.

- Basket – made of stainless steel, customized to the parts to be cleaned, perforated, multi-tire, and so on.

- Control Panel – independent operation, auto logic programmed control of individual cleaning pots. PID temperature control, SSR drive for heater control.

Notes: The unit could be entirely bespoke, we can design and tailor oven to the customer’s specification.